Technologies

We are committed to providing the highest quality, so our machinery park has been equipped with top-of-the-line printing machines and finishing equipment.

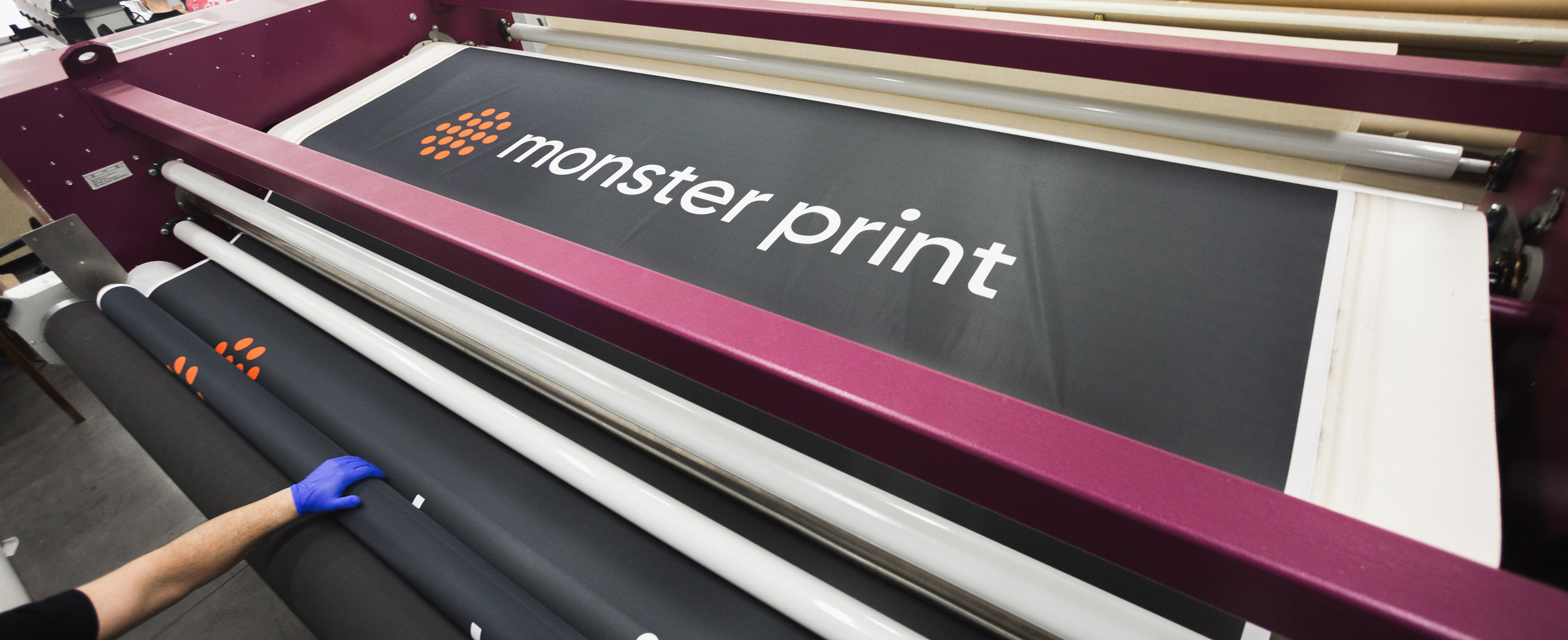

Sublimation printing

Characteristics

Sublimation printing is a unique technique that uses the phenomenon of sublimation in the printing process. It involves direct transition of dyes from a solid state to a gaseous state bypassing the liquid state. Sublimation printing is carried out using the direct method on the target material (Direct), or indirectly (DYE SUB transfer) using transfer paper. Then in devices such as calender - under high pressure and temperature - it is transferred to the target material, mainly to textile materials. Under the influence of temperature, polyester fabric fibres open, attracting dyes that penetrate deeply into the structure of the polyester, instead of settling on the surface. The end result is a coloured, odourless material. Thanks to the permanent dyeing of the fibres, the prints do not break, they are resistant to abrasion and creases. Prints can be washed and ironed.

Impact on the environment

Sublimation printing is one of the most ecological printing techniques. The inks used for sublimation printing are free of solvents and are produced on the basis of water. Sublimation printing chiefly uses environmentally friendly textile materials, without the addition of PVC. It is the sublimation printing technique that is used in all our products marked with the green ECO badge.

Machinery

Our machinery is equipped with the highest class sublimation printing machines, such as Durst Rhotex and Monti Antonio, which are leaders in their class of printing machines.

Characteristics

Sublimation printing is a unique technique that uses the phenomenon of sublimation in the printing process. It involves direct transition of dyes from a solid state to a gaseous state bypassing the liquid state. Sublimation printing is carried out using the direct method on the target material (Direct), or indirectly (DYE SUB transfer) using transfer paper. Then in devices such as calender - under high pressure and temperature - it is transferred to the target material, mainly to textile materials. Under the influence of temperature, polyester fabric fibres open, attracting dyes that penetrate deeply into the structure of the polyester, instead of settling on the surface. The end result is a coloured, odourless material. Thanks to the permanent dyeing of the fibres, the prints do not break, they are resistant to abrasion and creases. Prints can be washed and ironed.

Impact on the environment

Sublimation printing is one of the most ecological printing techniques. The inks used for sublimation printing are free of solvents and are produced on the basis of water. Sublimation printing chiefly uses environmentally friendly textile materials, without the addition of PVC. It is the sublimation printing technique that is used in all our products marked with the green ECO badge.

Machinery

Our machinery is equipped with the highest class sublimation printing machines, such as Durst Rhotex and Monti Antonio, which are leaders in their class of printing machines.

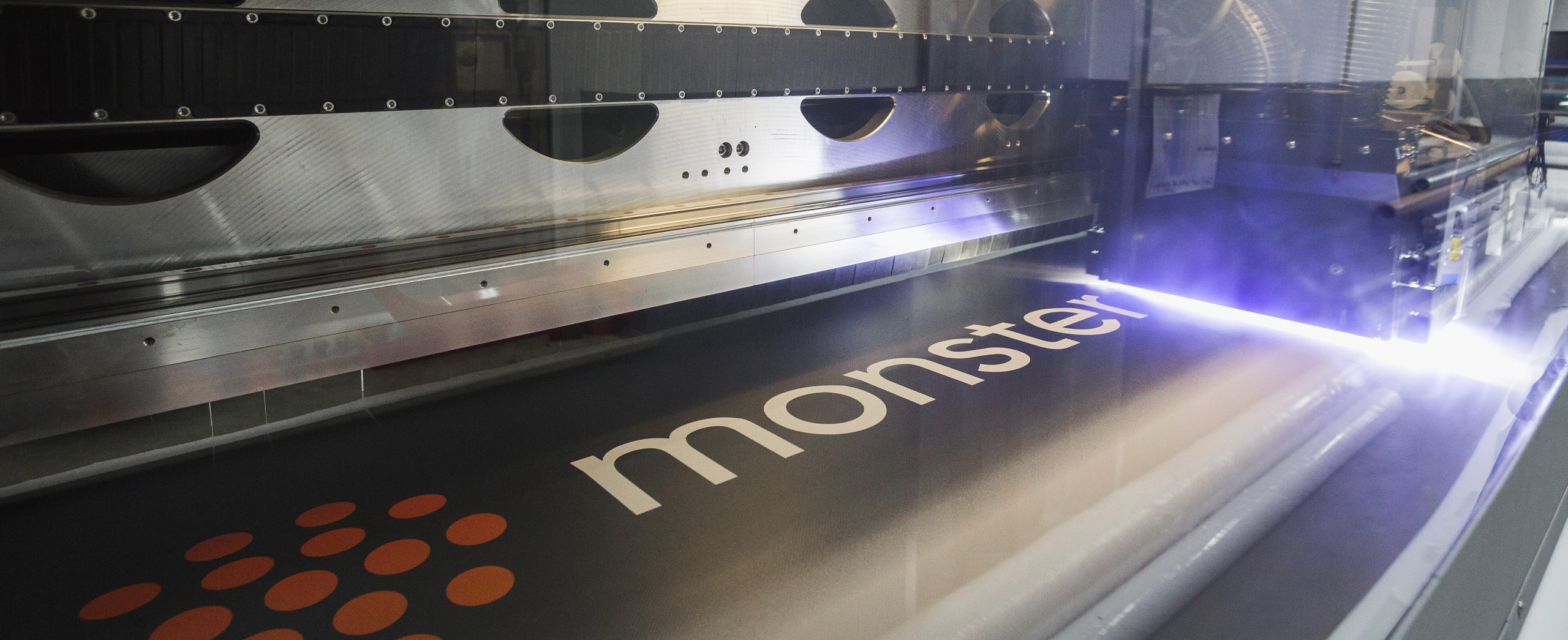

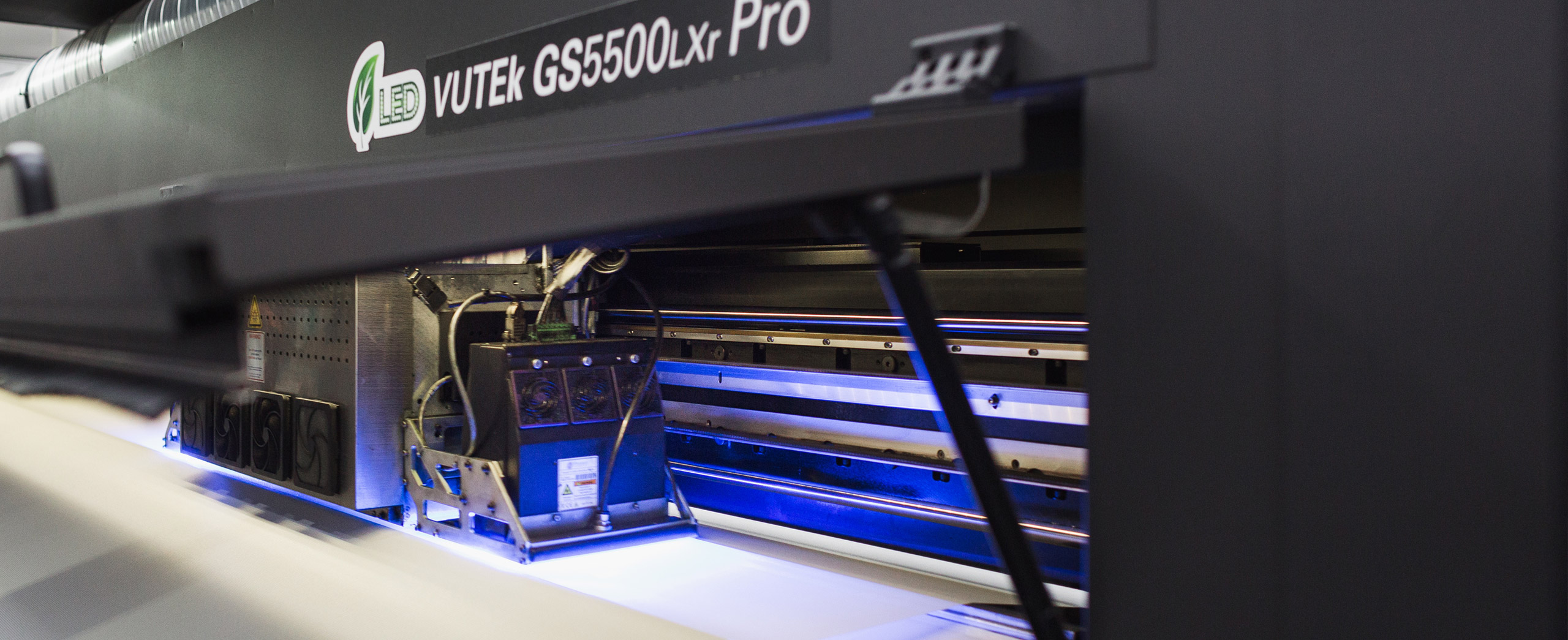

UV printing

Characteristics

The very process of printing in UV LED technology is similar to the process of printing with the use of ordinary ink-jet printers. The key differences, however, are the special inks in the form of liquid polymers used in the UV printing process and the process of fixing the print with UV light. Installed right next to the printing heads, LED lamps emit UV light, which initiates the polymerization process of the printed ink. As a result of this process, the liquid polymer cures, remaining on the surface of the material as a print in the form of a thin layer of durable plastic. The UV printing technology means that the print is immediately dry and ready for use or for further processing. UV printing does not require additional protection with varnish or protective laminate, which significantly speeds up the entire production. It is characterized by high colour fastness, quality and aesthetics. Prints are very durable and resistant to all weather conditions (water, moisture, sun) and damage. They are also less susceptible to scratches and abrasion of the graphics during its use.

Impact on the environment

UV printing is one of the more environmentally friendly printing techniques. UV inks do not emit harmful fumes, thanks to which UV prints can be used in both external and internal applications.

Machinery

Our machinery is equipped with the highest class UV printing machines produced by Durst and EFI, which are the absolute leaders in their class. They set the highest standards in industrial digital printing, providing unrivalled and previously unattainable quality and performance.

Characteristics

The very process of printing in UV LED technology is similar to the process of printing with the use of ordinary ink-jet printers. The key differences, however, are the special inks in the form of liquid polymers used in the UV printing process and the process of fixing the print with UV light. Installed right next to the printing heads, LED lamps emit UV light, which initiates the polymerization process of the printed ink. As a result of this process, the liquid polymer cures, remaining on the surface of the material as a print in the form of a thin layer of durable plastic. The UV printing technology means that the print is immediately dry and ready for use or for further processing. UV printing does not require additional protection with varnish or protective laminate, which significantly speeds up the entire production. It is characterized by high colour fastness, quality and aesthetics. Prints are very durable and resistant to all weather conditions (water, moisture, sun) and damage. They are also less susceptible to scratches and abrasion of the graphics during its use.

Impact on the environment

UV printing is one of the more environmentally friendly printing techniques. UV inks do not emit harmful fumes, thanks to which UV prints can be used in both external and internal applications.

Machinery

Our machinery is equipped with the highest class UV printing machines produced by Durst and EFI, which are the absolute leaders in their class. They set the highest standards in industrial digital printing, providing unrivalled and previously unattainable quality and performance.

Eco-solvent printing

Characteristics

Eco-solvent printing is an improved, ecological version of traditional solvent printing, in which the ink has been stripped of harmful chemical compounds. Eco-solvent printing mainly uses materials such as films, papers, wallpapers, canvasses. Photographic print quality guarantees vivid colours. The elimination of harmful chemicals from eco-solvent paints reduced its resistance to weather conditions. Due to the lower resistance to atmospheric conditions, eco-solvent prints are intended mainly for interiors. They are also used outdoors, but the service life in such conditions is shorter due to changing weather conditions. In order to ensure the longest possible lifetime, we recommend securing the print with a laminate that reduces the effects of sun, moisture and rain on the print, as well as protects against UV radiation and protects the print from scratches and mechanical damage.

Impact on the environment

In eco-solvent printing, inks are used, produced on the basis of organic solvents, which are more environmentally friendly than traditional solvent inks. This technology, however, is less environmentally friendly than sublimation printing.

Machinery

Our machinery is equipped with Roland printing plotters, which are leaders in their class.

Characteristics

Eco-solvent printing is an improved, ecological version of traditional solvent printing, in which the ink has been stripped of harmful chemical compounds. Eco-solvent printing mainly uses materials such as films, papers, wallpapers, canvasses. Photographic print quality guarantees vivid colours. The elimination of harmful chemicals from eco-solvent paints reduced its resistance to weather conditions. Due to the lower resistance to atmospheric conditions, eco-solvent prints are intended mainly for interiors. They are also used outdoors, but the service life in such conditions is shorter due to changing weather conditions. In order to ensure the longest possible lifetime, we recommend securing the print with a laminate that reduces the effects of sun, moisture and rain on the print, as well as protects against UV radiation and protects the print from scratches and mechanical damage.

Impact on the environment

In eco-solvent printing, inks are used, produced on the basis of organic solvents, which are more environmentally friendly than traditional solvent inks. This technology, however, is less environmentally friendly than sublimation printing.

Machinery

Our machinery is equipped with Roland printing plotters, which are leaders in their class.

The finishing department

Our finishing department is served by an excellent team of qualified specialists with many years of experience. Thanks to the wide spectrum of devices, we can apply any type of finish. We frame, weld, sew, make eyelets, pack, and all these activities are performed under the supervision of the quality control department. Our sewing and the finishing department are equipped with the latest technologies available on the market. We use machines from brands such as Leister, Matic, Juki, which are world leaders in their class of devices.

Our finishing department is served by an excellent team of qualified specialists with many years of experience. Thanks to the wide spectrum of devices, we can apply any type of finish. We frame, weld, sew, make eyelets, pack, and all these activities are performed under the supervision of the quality control department. Our sewing and the finishing department are equipped with the latest technologies available on the market. We use machines from brands such as Leister, Matic, Juki, which are world leaders in their class of devices.

Process automation

In accordance with Kaizen philosophy we strive to develop our company by constantly improving and streamlining all production and technological processes. We introduce solutions and adapt software that increases the quality of products and increases the ergonomics in the workplace. Full automation of purchase order circulation and production processes allows us to process orders quickly and always on time, while maintaining the highest quality of workmanship.

In accordance with Kaizen philosophy we strive to develop our company by constantly improving and streamlining all production and technological processes. We introduce solutions and adapt software that increases the quality of products and increases the ergonomics in the workplace. Full automation of purchase order circulation and production processes allows us to process orders quickly and always on time, while maintaining the highest quality of workmanship.

Interested in cooperating with us?

Call us

+48 17 867 47 64